- 简体中文

- English

Learn "Foam pump"

As a foam pump that only caught fire in recent years, I believe most people have more than N why in their minds? Such a small pump head is so magical, a press can give so much foam. The traditional emulsion pump we use in daily life needs and water to rub out the foam, and it only needs to press so gently can extrude rich and delicate foam, is really save time and effort and worry, what is its working principle after all? In the thirst for knowledge of the drive, xiaobianin-depth factory workshop to find the most senior processing division, with you to travel the ocean of knowledge ~~~ explore the foam pump after all!

Turns out, it's about the composition of the foam pump!

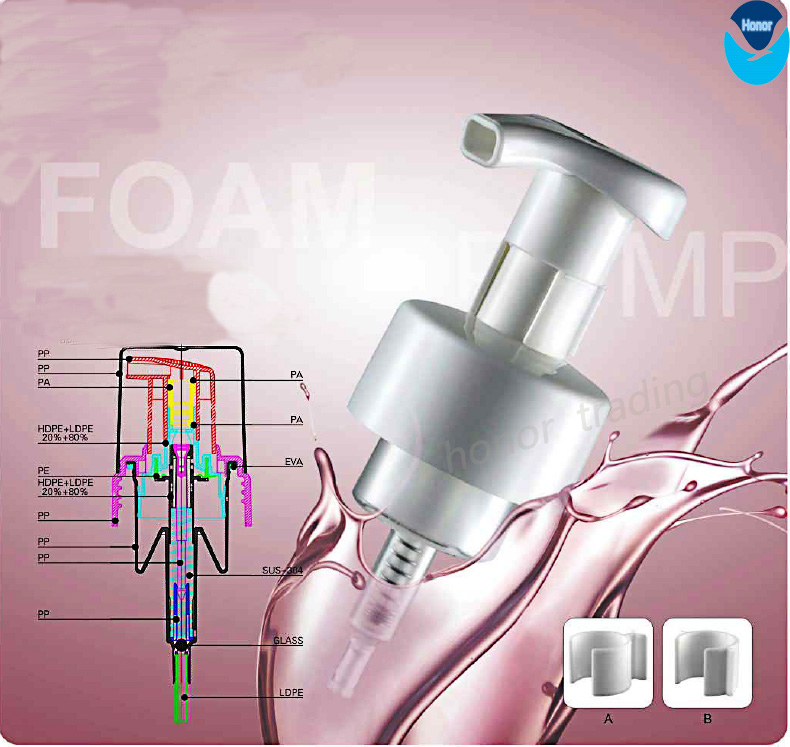

Foam pump head belongs to the distributor in cosmetic packaging materials, and the composition is relatively complex, including: dust cover, press head, screw cover, pump body, nylon mesh, glass bead, gasket, spring, pull rod and glass bead, etc.

It is precisely the cooperation of so many precision components can constitute a complete foam pump head. The sparrow is small, but it has all its faults.

And its work principle is that the pump head at work, press the pump head after loosening, built-in bounce of the spring push the piston upward, inside glass beads check valve in the closed state, the liquid be inhaled and upward along the outlet, the surface active agent is mixed with air in liquid, then after a nylon mesh side by side out of the pump. Therefore, this requires high precision of the device, so as to ensure good air tightness, which we usually take -0.05 to -0.06mpa as the guarantee standard.

Due to the complexity of foam pump structure, as long as one of the precision components of the defective can directly affect the quality of the whole pump head, so producers must strictly control the quality of products in the production process.

As a professional foam pump head supplier with many years of experience, our company knows the importance of foam pump quality control. Due to its own high standards and strict requirements, every foam pump product manufactured by our company goes through two strict procedures of precision instruments and careful manual inspection, so that every part and every finished product is fully inspected and finally delivered to customers.

We also always believe that being responsible to our customers means being responsible to ourselves. The trust of customers is the basis of long-term cooperation between the two sides. We look forward to becoming your most reliable partner in the future.

Learn "Foam pump"

As a foam pump that only caught fire in recent years, I believe most people have more than N why in their minds? Such a small pump head is so magical, a press can give so much foam. The traditional emulsion pump we use in daily life needs and water to rub out the foam, and it only needs to press so gently can extrude rich and delicate foam, is really save time and effort and worry, what is its working principle after all? In the thirst for knowledge of the drive, xiaobianin-depth factory workshop to find the most senior processing division, with you to travel the ocean of knowledge ~~~ explore the foam pump after all!

Turns out, it's about the composition of the foam pump!

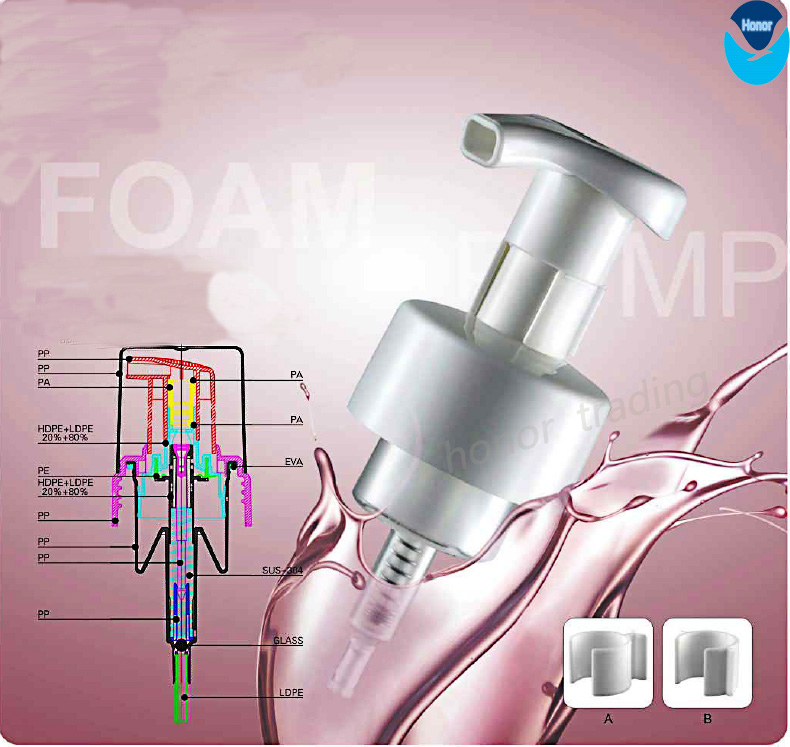

Foam pump head belongs to the distributor in cosmetic packaging materials, and the composition is relatively complex, including: dust cover, press head, screw cover, pump body, nylon mesh, glass bead, gasket, spring, pull rod and glass bead, etc.

It is precisely the cooperation of so many precision components can constitute a complete foam pump head. The sparrow is small, but it has all its faults.

And its work principle is that the pump head at work, press the pump head after loosening, built-in bounce of the spring push the piston upward, inside glass beads check valve in the closed state, the liquid be inhaled and upward along the outlet, the surface active agent is mixed with air in liquid, then after a nylon mesh side by side out of the pump. Therefore, this requires high precision of the device, so as to ensure good air tightness, which we usually take -0.05 to -0.06mpa as the guarantee standard.

Due to the complexity of foam pump structure, as long as one of the precision components of the defective can directly affect the quality of the whole pump head, so producers must strictly control the quality of products in the production process.

As a professional foam pump head supplier with many years of experience, our company knows the importance of foam pump quality control. Due to its own high standards and strict requirements, every foam pump product manufactured by our company goes through two strict procedures of precision instruments and careful manual inspection, so that every part and every finished product is fully inspected and finally delivered to customers.

We also always believe that being responsible to our customers means being responsible to ourselves. The trust of customers is the basis of long-term cooperation between the two sides. We look forward to becoming your most reliable partner in the future.